BIQU H2 V2S - Direct Extruder

| Category: | Direct |

|---|

Main advantages:

Lightweight and compact

Low weight, low inertia, better precision.

Excellent workmanship

The 6061 T6 aluminum alloy body ensures long-lasting performance even in extreme conditions.

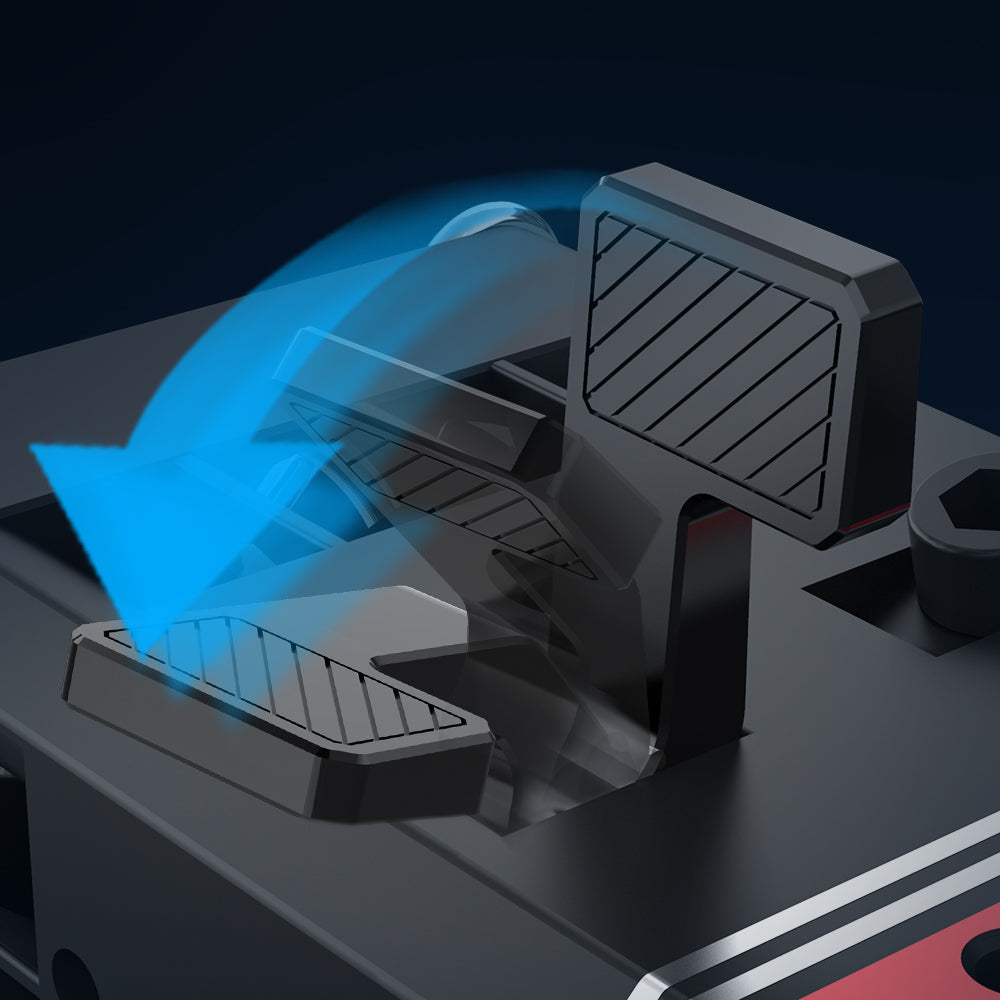

Easier filament replacement

You don't need to hold the improved lever to release. Simply flip it.

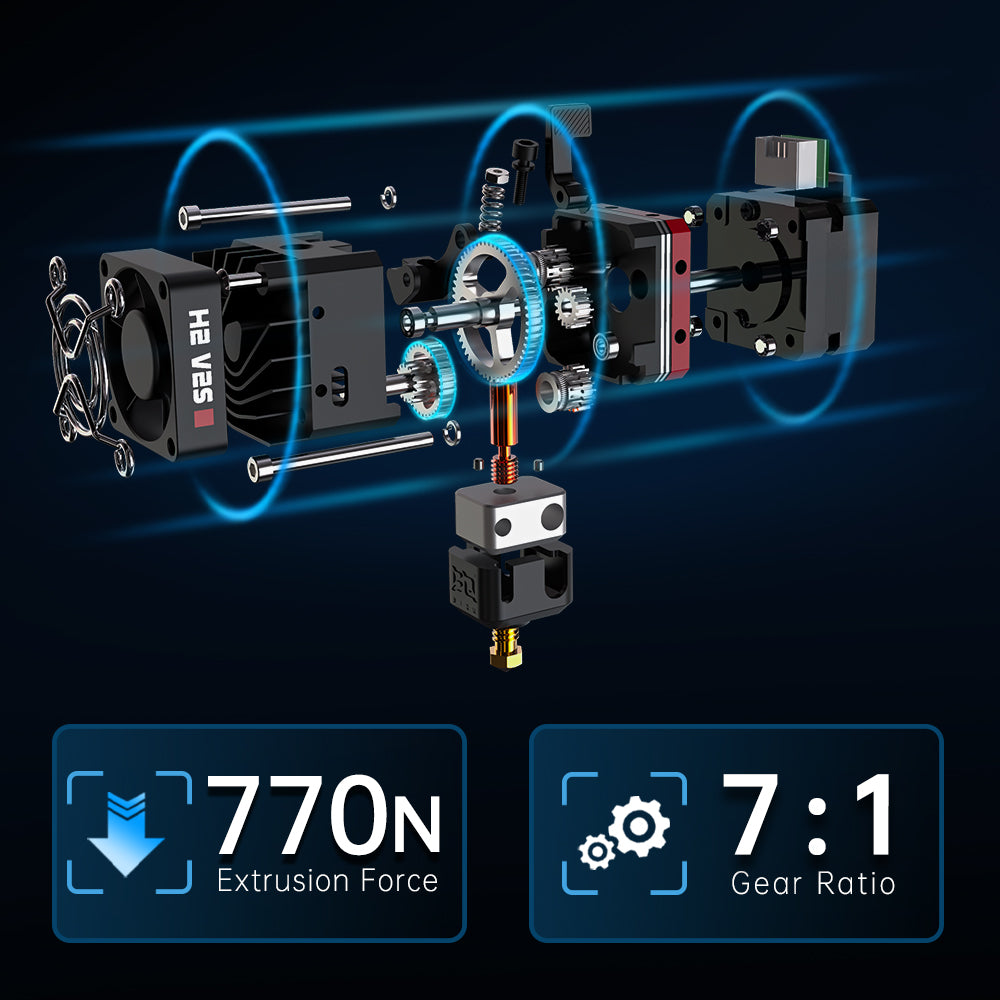

Powerful extruder

Dual drive and 7:1 gear ratio ensure exceptional extrusion force while maintaining compact dimensions

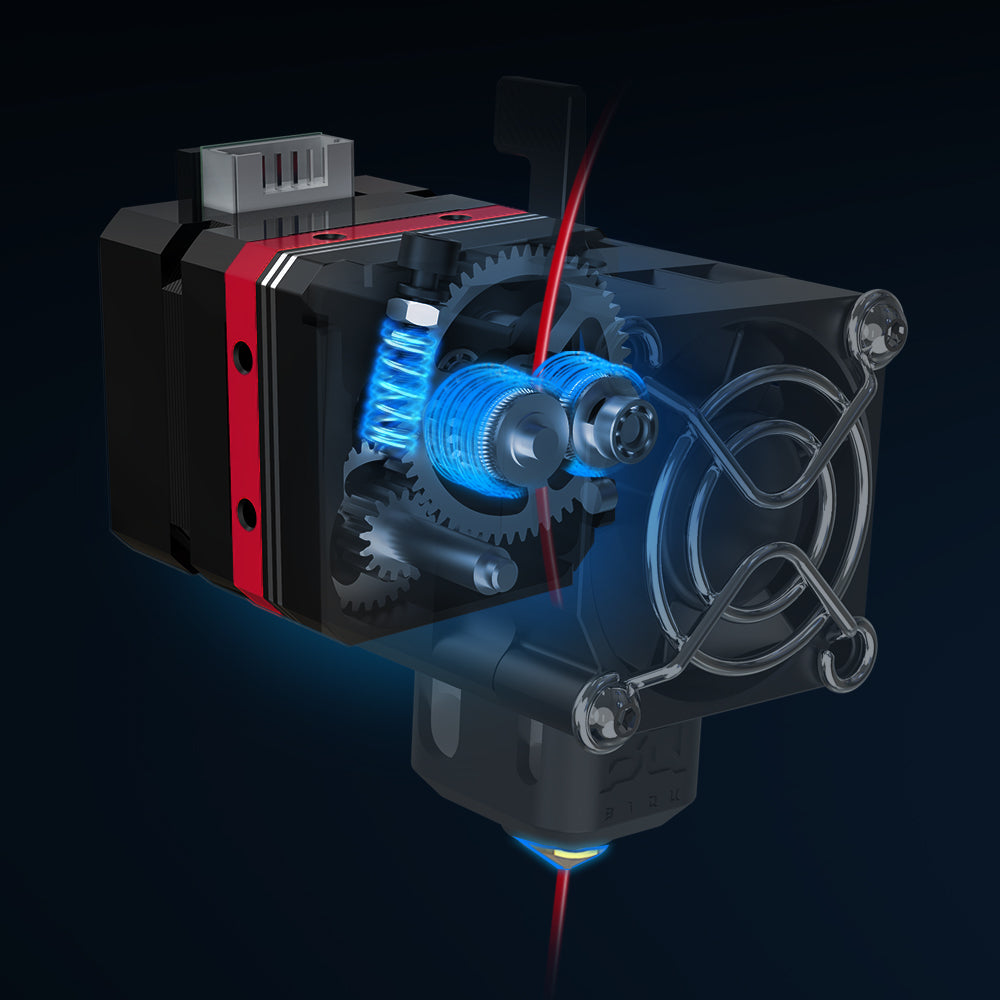

Excellent choice for flexible filament

Adjust the screw tensioner to match the pressure of the drive gear and improve

printing with flexible filament.

High-temperature printing

The bimetallic heatbreak allows for high-temperature printing at 270°C with a silicone cap for insulation.

This temperature is sufficient for most commonly used materials.

Perfect compatibility

Compatible with many materials, from PLA and ABS to TPU, Nylon, and PETG.

Packaging

The kit includes the H2 V2S extruder itself, a 35x35x10 fan (24V),

fan grille, HT-NTC100K thermistor, 24V 40W heater,

a stepper motor cable with a DuPont connector and assembly keys.

Product Information:

One of the best upgrades you can give your printer. Thanks to its simple design and low weight, you can put it on almost any printer. In version 1.0, we could first see it on BIQU BX printers.

The V2 version, compared to V1.0, differs by the removal of the PTFE tube, which has been replaced by an all-metal heatbreak. Another improvement in V2 is the stainless steel gears and holes for the heatbreak grub screws, so you don't have to disassemble the entire hotend when replacing the heatbreak.

The V2S version is a few grams lighter than the V2 version. The original lever for filament removal now has tension adjustment. And for quick replacement, you don't need to hold the lever, simply flip it. It also includes several new mounting holes for attaching accessories.

Lightweight, powerful, foolproof. For us, definitely the best choice.

Parameters:

Extruder type: Direct drive

Supported filament diameter: 1.75 ± 0.05 mm

Supported temperatures: max. 270 °C

Weight: 195 g (including heat block, heater, thermistor, and fan)

Gear ratio: 7:1

Maximum extrusion force: 7.7 kg (depending on filament)

Extrusion volume: 600 mm3/min (depending on filament)

Number of steps per mm when stepping 16x (steps per mm): 932 (calibration required)

Recommended motor current: 800mA

Nozzle type: E3D (original is modified nozzle, E3D works without problems)

Nozzle with PTFE coating: E3D

Hardened Nozzles: E3D

Thermistor type: NTC 3950 100k

Heater type: 24 V 40 W

Hotend cooling fan type: 35x35x10 24 V

Heatbreak type: bimetallic

Heatblock cover: silicone H2 V2

Video Tutorial for Extruder BIQU H2 V1.0

(assembly of H2 V2.0, V2S is identical)

A bracket is required to attach it to the printer, which varies depending on the printer.Basic brackets are provided by the manufacturer, but today there are many improved brackets available for free download. For the Ender 3 V2 printer, a user createdamodified bracket for us. We recommend using a 50x50x15 24 V radial fan with the extruder to cool the print. There are also many fan brackets available for download. We personally use the proven one-piece bracket .

The package includes a stepper motor cable with a DuPont connector, which may not always fit your motherboard. Please verify and order the cable variant with the XH2.54 connector, also in the 2-meter variant. Since the extruder has a gearbox, the motor will rotate in reverse after connection. You can reverse the motor direction in the settings of some printers. Another and most commonly used option is to modify the cable, swapping the green core with the black core.